Shin-Etsu Sepla Film is a super engineering plastic film made of PEEK.

[Industrial field]

Smartphone, Home electric appliances, Automotive Industry, Electrical Products, Medical, Aviation, Pipeline, Semiconductor Materials, Agriculture

It features excellent heat tolerance, sliding properties, and chemical resistance. Its advantages also include its low water absorbing property and low dielectric constant.

[Applications]

- Diaphragm for speakers and receivers

- Impregnation for CFRTP

- Material for copper wire coverings

- Motor insulation

- Exterior material for batteries

- Material for medical equipment components

- Semiconductor process cover films

Low crystallinity grade

- thickness 3-9µm

- width 650mm

- length 1,000m

- core diameter 6 inch

High crystallinity grade

- thickness 50-250µm

- width 650mm

- length 50µm:300m

250µm:100m - core diameter 6 inch

Please contact us for product specifications such as thickness, width, length, and material of core.

Characteristic table

1. Mechanical properties

|

||||||||||||||||||||||||||||||||

(These property values are measured values and not guaranteed values.)

2. Electrical properties

|

Item |

High crystallinity grade 50μm |

Test method |

|

Dielectric Constant(1GHz) |

3.0 |

Cavity prturibation method (Comply with ASTM D2520) 23±1℃ 50±5%RH |

|

Dissipation factor(1GHz) |

0.003 |

|

|

Dielectric breakdown voltage(kV) |

8.7 |

IEC 60243-1 23±2℃ 50±5%RH |

|

Dielectric breakdown strength(kV/mm) |

180 |

|

|

Volume resistivity(Ω・㎝) |

9.8×10~{16} |

JIS K6911 Input voltage:DC500V |

(These property values are measured values and not guaranteed values.)

3. Thermal properties

|

(These property values are measured values and not guaranteed values.)

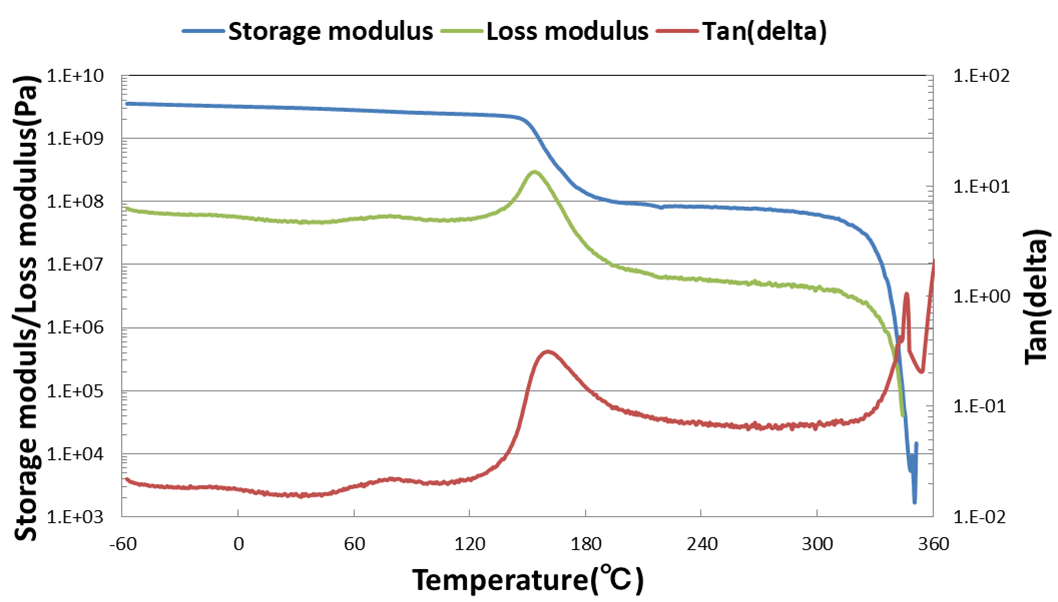

Figure1. Heat resistance 【Dynamic viscoelasticity, MD】

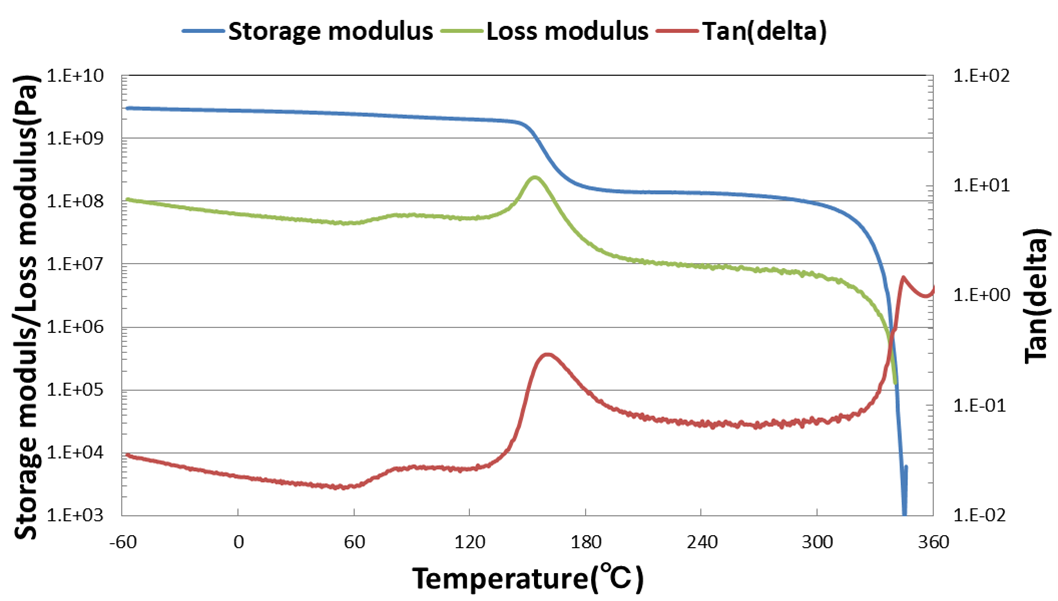

Figure2. Heat resistance 【Dynamic viscoelasticity, TD】

4. Chemical properties

|

Item |

High crystalline grade (thickness) |

Test method |

|

|

Specific gravity |

1.3(100μm) |

JIS K7112 |

|

|

Water absorption(%) |

0.3(50μm) |

JIS K7209 A method 23℃×24hr |

|

|

Water permeability(g/㎡・24hr.) |

15(50μm) |

JIS Z0208 |

|

|

Gas permeability (mol/㎡・s・Pa) |

O_{2} |

7.7×10~{-13}(50μm) |

JIS K7126 |

|

N_{2} |

2.1×10~{-13}(50μm) |

||

|

CO_{2} |

4.4×10~{-12}(50μm) |

||

|

Chemical resistance |

Hydrochlonic acid、37% |

Retention of modulus:101% |

ASTM D638 Immersed in the fluids for 30 days |

|

Nitric acid、30% |

Retention of modulus:100% |

||

|

Sulfurric acid、20% |

Retention of modulus:102% |

||

|

Potassium hydroxide、45% |

Retention of modulus:101% |

||

|

Ethanol |

Retention of modulus:105% |

||

|

Toluene |

Retention of modulus:98% |

||

(These property values are measured values and not guaranteed values.)

*"Shin-Etsu Sepla Film" is a registered trademark of Shin-Etsu Chemical Co., Ltd.