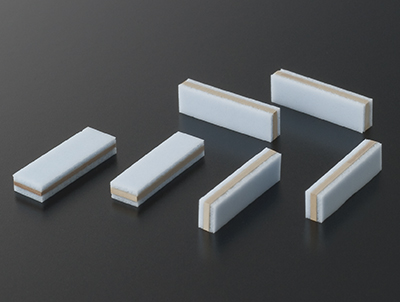

This is a zebra-type interconnector which consists of conductive and insulating silicone rubber arranged alternately and both sides are supported by insulating spongy silicone rubber with low-hardness.

This type is suitable for connection stability, and is used as connector between LCD and printed circuit board or PCB, especially electronic parts that cannot be soldered.

[Industrial field]

Automobile, Information device, Home electric appliance

- Silver particles, that are used as conductive elements, make the stable connection with low resistance. It is suitable for connecting board-to-board and electronic component to a board as an alternative to soldering.

- The flexibility of silicone rubber supporting fine metal wires provides excellent absorption of dimensional variation between boards, excellent reliability, and superior resistance to vibration and shock.

[Applications]

- Connection of devices(Speakers, Microphones, etc.)to PCB

- Connection of board-to-board

- Anti-Tamper Switch

- Just compressing and holding the connector between the electrodes can save space in the connections and make the devices smaller and thinner.

- The connector does not need to be positioned (random connection), because multiple conductive pass in it contact the electrode.

- Solderless connection allows easy assembly and disassembly.

- Since the connection is maintained by the reaction force of the silicone rubber, a stable connection can be achieved even in equipment that requires high resistance to vibration and shock.

- The conductive element is a silver particle. It is suitable for connections that require low resistance, high current capacity, and no damage to the electrode.

- Compression connection type connector: Conductive silicone rubber using silver particles and insulating silicone rubber are arranged at a low pitch, and both sides are supported by insulating silicone rubber.

- Elastomeric interconnector in which conductive silicone rubber with silver particles and insulating silicone rubber are arranged at a low pitch, and both sides are supported by insulating silicone rubber.

- MS-G type that uses foamed silicone rubber for the support part, and MS-Z type that uses thin silicone rubber for the support part.

Introduction video of "Shin-Etsu Inter-Connector"

Dimension and tolerance

|

|||||||||||||||||||||||||||||||||||

HW/2

※Gas barrier bag is the standard packing style.

※Please refer to the MS type technical material when handling.

※Design guide is available as a reference to determine dimensions.

※MS-G spec. (0.4Z) is also available.

Shin-Etsu Inter-Connector has been registered in European Community, TM No.000299016, and in the United States of America, TM No.2078941.

Outline dimensions

Basic properties

| Item | Unit | MS-G | MS-Z |

|---|---|---|---|

| Volume resistivity ※ | Ω/m | 1 x 10~{-5} | 1 x 10~{-5} |

| Insulation resistance ※ | MΩ | 1 x 10~{3}≦ | 1 x 10~{3}≦ |

| Compression set | % | ≦10 | ≦10 |

| Operating temperature range | ºC | -25~85 | -25~85 |

The test method is based upon JIS K 6249.

The test marked with ※ is carried out with Shin-Etsu's own method.

Compression curves

※Sample size

MS-Z 0.1P x 9.5L x 3.2H x 1.6W

MS-G 0.1P x 9.5L x 3.2H x 1.6W x 0.8Z

Resistance-compressibility curves

※Sample size

MS-Z 0.1P x 9.5L x 3.2H x 1.6W

MS-G 0.1P x 9.5L x 3.2H x 1.6W x 0.8Z

Note

Every item or numerical value indicated herein is measured by Shin-Etsu and out of guarantee.

The quality of the connector, which has been already assembled, is out of guarantee.

Please make sure to see about the purpose/conditions of use and practice your own test. Industrial ownership like patent doesn't guarantee the usage of the connector.

Catalog