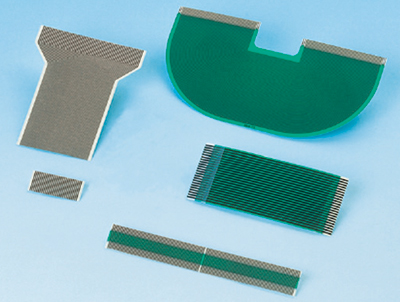

This is an anisotropic conductive heat seal connector for connection between LCD and PCB which has carbon conductive lines.

[Industrial field]

Automobile, Information device, Home electric appliance

-

It is a heat seal type in low temperature and storage at room temperature is allowed.

[Applications]

- Connection between LCD and printed circuit board (Automobile products, watches,digital cameras, electronic dictionaries, industrial equipments)

- This is a heat seal connector made from polyester films with carbon conductive lines.

- It is used for connection by heat-sealing with anisotropic conductive adhesive. Connection by ZIF type can be also used.

- We can supply it with the shape of requirement of customer. And we have standard type which needs no initial cost.

- Heat seal connector made from polyester films with carbon lines is coated by anisotropic conductive adhesive.

Dimension and tolerance

|

||||||||||||||||||||||||||||||||||||||

Outline dimensions

Construction

|

Basic properties

|

Bonding conditions range

|

(1) This temperature should be applied only to the bonding area.

(2) Time (2) means keeping one at reaching the adhesive temperature (1)

※Surface should be free of dust and contamination.

※Above "BONDING CONDITION" is not specification. It is only condition which are got in our test. Your proper condition depends on heatsealing machine, material of jig, thichness and material of cushion, size and material of adherent, environment in your process and so on. Evaluation in your process should be necessary by yourself.

※The test is carried out with Shin-Etsu's own method.

※The above conditions are provided only for reference and are based upon our company's in-house tests. Applicable conditions will vary depending on the thermal capacity of equipment, cushioning material, thickness, adhesive body size, material, exoergic properties of the lower supporting jig, and a variety of other environmental factors. As such, the above conditions should be used only for reference and implemented only after thorough testing.

Note

Every item or numerical value indicated herein is measured by Shin-Etsu and out of guarantee.

The quality of the connector, which has been already assembled, is out of guarantee.

Please make sure to see about the purpose/conditions of use and practice your own test. Industrial ownership like patent doesn't guarantee the usage of the connector.

Catalog