Creating a new future through material compounding technologies

We cater to the new needs of customers through R&D efforts made using all of our material compounding technologies and expertise in processing, which have been accumulated over many years.

-

.jpg) 2020/06/30

『EXELAST®』 SE Series

2020/06/30

『EXELAST®』 SE Series

Rigid and Soft PVC compound that could be molded by various ways such as extrusion, injection, and blow molding.

- Low friction PVC compound

-

2020/06/30

『EXELAST®』 SX Series

2020/06/30

『EXELAST®』 SX Series

Olefin compound that is used for surrounding parts of automotive window.

- Low friction TPV compound

-

2020/06/30

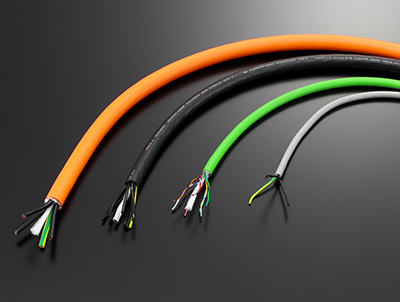

『EXELAST®』 EC Series

2020/06/30

『EXELAST®』 EC Series

Thermoplastic Urethane(TPU) compound with various functions such as oil resistance, heat resistance, low friction, abrasion resistance, and flame resistance according to the application.

- Low friction TPU compound

-

2020/06/30

『SEPLEGYDA®』

2020/06/30

『SEPLEGYDA®』

SEPLEGYDA is possible to provide thin conductive layer by coating. There are many formulations depending on resistivity, from low resistance(10²~10³Ω/sq) to high resistance of anti-static area(10⁴~10¹⁰Ω/sq).

- Polythiophene-base conductive polymer

-

2020/06/30

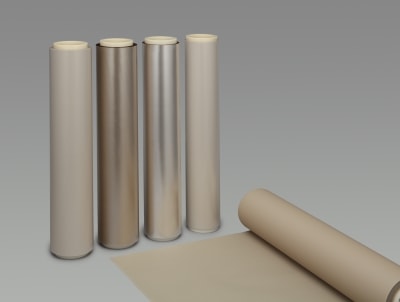

『Shin-Etsu Sepla Film®』

2020/06/30

『Shin-Etsu Sepla Film®』

Shin-Etsu Sepla Film® is a super engineering plastic film . It is a non-stretched film made of PEEK, a super engineering plastic. It is available as either a thick or thin film.

- The high-functioning engineering plastic film